I do not know when, the thermos cup and health care like a pair of twins, are bound together. As a common drinking water tool in life, seemingly ordinary thermos cups hide a market of tens of billions behind, and sales are still rising year by year, from 18.63 billion yuan in 2016 to more than 28 billion yuan in 2021. With the improvement of national health awareness and living standards, coupled with the strong demand for intelligent, personalized, energy saving and environmental protection, the market size of thermos cups will be further expanded.

The "rising sound" of the industry continues, although it has brought driving forces for the rapid development of thermos cup manufacturers, but it has also further intensified market competition. At the same time, when the demographic dividend fades, enterprises have to face labor shortages, rising costs and other problems. The rapid development and application of automation and intelligent technology not only alleviates the dilemma of "labor difficulty" of enterprises, but also further improves product quality. SRT uses Industry 4.0 technology to create a digital production line for thermos cups to achieve flexible deployment and intelligent production.

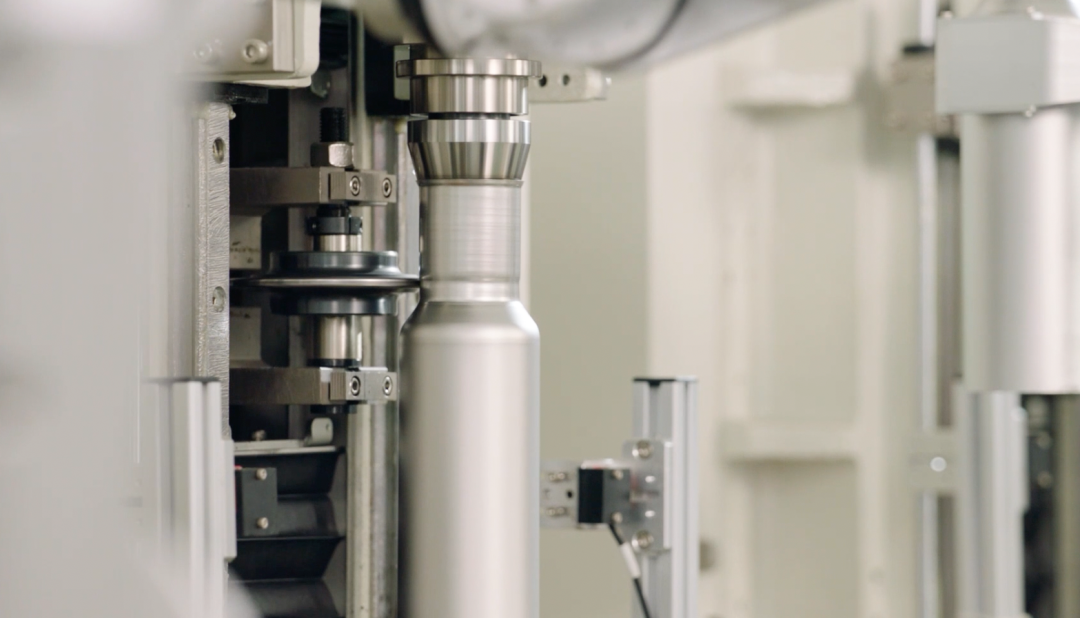

Integrated machine to solve the trouble of changing type

Uniform, coordinated, will be more efficient, SRT knows this. The whole line of SRT thermos cup digital production line adopts modular and standardized integrated machine design to realize the one-click switching of various processes such as laser parting cup, shrink mouth, shrink waterproof neck, flaring, rolling thread, etc. One machine can switch a variety of processes, improve the expansion of the production line, improve the production efficiency of the production line, and solve the installation and change of the line body caused by the traditional differentiated machine.

In addition, the whole line beats faster and the production capacity is higher. The average time of a single cup is only 6s, and the capacity of a single shift can reach 5800pcs in ten hours, greatly improving the utilization rate of the line body.

With flexible clamp, non-destructive transfer

In the traditional thermos cup production line, the loss of thermos cup in the production process is always not a small number. In order to reduce production losses, SRT is equipped with robots to shift loads between machines, reducing manual intervention and improving production line stability. At the same time, SRT also adopts the patented technology of non-destructive load transfer to realize the non-destructive handling of the thermos cup.

Compared with the traditional metalworking line, the SRT thermal cup digital production line has a higher yield, and the yield can reach more than 99%, which largely avoids the direct economic loss caused by steel loss.

Modular design, one-click mold change

In view of the long mold change time of traditional thermos cup production line, SRT thermos cup digital production line has also been innovatively optimized. SRT thermos cup digital production line adopts one-click mold replacement mode to achieve rapid mold change function, mold change time is controlled within two hours, built-in program can replace product model with one click, reduce the replacement cup time, highly optimize production capacity, greatly reduce production time and cost.

Digital production, data upload to the cloud

In the digital age, digital technology is a standard part of automated production lines. The SRT thermos cup digital production line is equipped with a digital port, which can directly upload the machine processing parameters to the cloud to realize the digital process. In improving the quality of thermos cup production, improve production efficiency at the same time, greatly reduce labor costs.

For the traditional manufacturing industry, with the intensification of industry competition and the improvement of consumer demand, automation is like a black hole, no matter whether the enterprise is active or passive, it can not escape the fate of automation. Only enterprises that truly complete their own automation "revolution" can join the world's advanced manufacturing industry. SRT, as a supplier of intelligent equipment and production lines for the thermal insulation cup industry, provides whole-plant planning services and turnkey projects for production lines, enabling the construction of numerical cloud platform and intelligent manufacturing upgrade for the thermal insulation cup industry.