lead

Through this article, we will focus on answering your questions:

✔ Trillion-level blue Ocean market "pre-" and" system "?

✔ How can SRT be an important player in every service process, from original ingredients to finished prefabricated dishes?

✔ What blocking points have SRT products and solutions cleared for customers in the prepared vegetables industry?

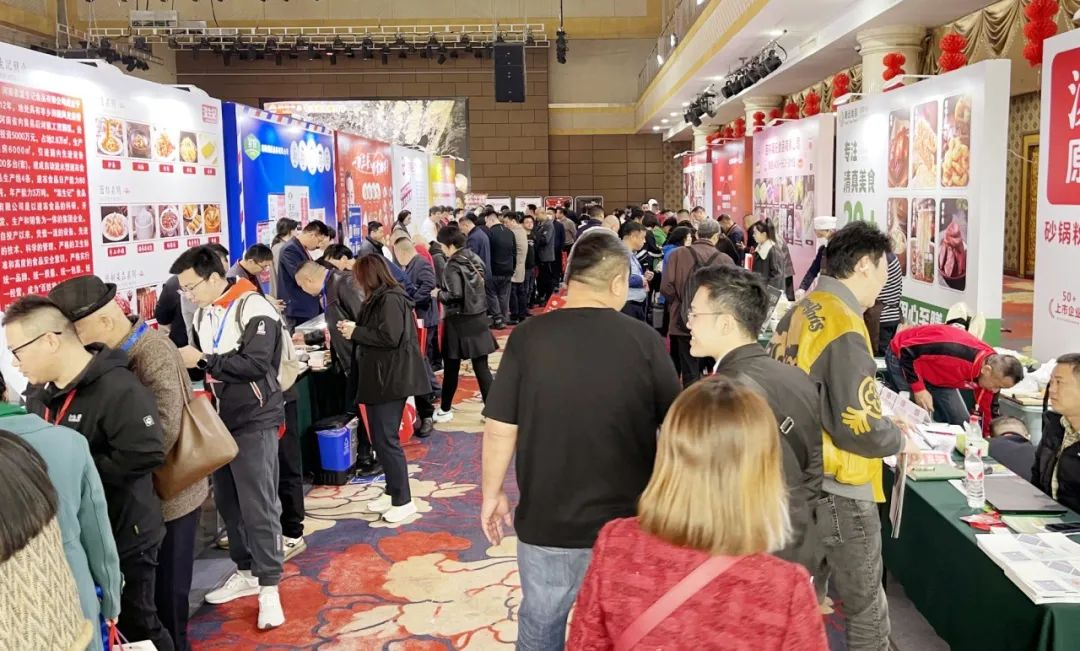

On March 16, in order to better promote the healthy development of China's prepared dish industry, the "China Prepared Dish Industry Development Conference" sponsored by Prepared Dish Online was held in Beijing Dahongmen International Convention and Exhibition Center. SRT air conditioning packaging testing and demonstration program participated in the conference to discuss the core pain points of prepared dish production with the industry, and share the latest research and development results and project experience.

In recent years, with the continuous growth of the scale of the prepared dish industry, more and more prepared dish enterprises have begun to use automated and intelligent tools to achieve standardized production in order to increase production capacity and ensure food safety. At the same time, SRT is always insight into the market demand, relying on the leading technology, focusing on the characteristics of innovation, professionalism, safety and green, and constantly introducing more adaptable products and equipment and comprehensive solutions, and building momentum for the prepared food industry with strong technology upgrading and comprehensive solution service capabilities.

Trillion blue ocean market

Automation/intelligent production brings a new round of "table Revolution"

In 2024, the "Government Work Report" proposed to cultivate and develop new quality productivity, and further guide the research and development, production and promotion of the prepared vegetable industry into a new stage; It is expected that by 2026, the scale of the prefabricated vegetable market will reach 1072 billion yuan, which is expected to become the next trillion-level market.

The huge market "giant baby" is hungry for food, and continues to promote the scientific and technological change of upstream and downstream prefabricated vegetable equipment. As an early software technology company in the field of prepared dishes, SRT focuses on the separation of the two core areas of "pre-preparation" and "preparation", and focuses on the design and development of new functions, new materials and new equipment, so as to achieve a rapid response to customer needs and market trends. At present, from the picking of raw materials, pre-treatment distribution sorting and packaging, to deep processing (detection of finished products, packing/box), to the storage and logistics of prepared vegetables, and finally to the business terminal, each automated and intelligent link can see the figure of SRT.

01 Pre: Pre-automation of source intervention of food materials

Prefabricated vegetables are an important means to promote the food and industrialization of agricultural products and improve the added value of "agriculture, rural areas and farmers". The modernization of raw material supply areas directly affects the sustainable development of the whole prefabricated vegetables industry.

SRT has been involved in modern agriculture since its inception. Among them, the flexible claws independently developed by SRT, designed to imitate starfish, and can simulate human hands have been widely used in automated farm picking, fruit and vegetable sorting, meat quick-frozen goods transport and other links, becoming an important participant in building a "modern smart factory", helping customers in the food industry to complete "from food materials to finished product output," Every dish is safe and traceable "table revolution.

【Food industry flexible grasping display scheme】

02 system: process standardization, create more application scenarios

SRT firmly believes that the production of prefabricated vegetables is a upstream and downstream "mortise and tenon combination", just like a chicken from the initial meat cleaning, after division, ingredients, testing, packaging, refrigeration, transportation, etc., in order to become a braised chicken prefabricated dish on the table, which shows that the whole industry chain needs more professional, intelligent, green equipment and production line.

Based on this, SRT through long-term customer cooperation, on the basis of the application of soft robot technology, continuously increase the research and development investment in food standardized production lines, through the construction of a more universal production space, to meet the needs of customers "only with a small number of manual to complete the whole process of production".

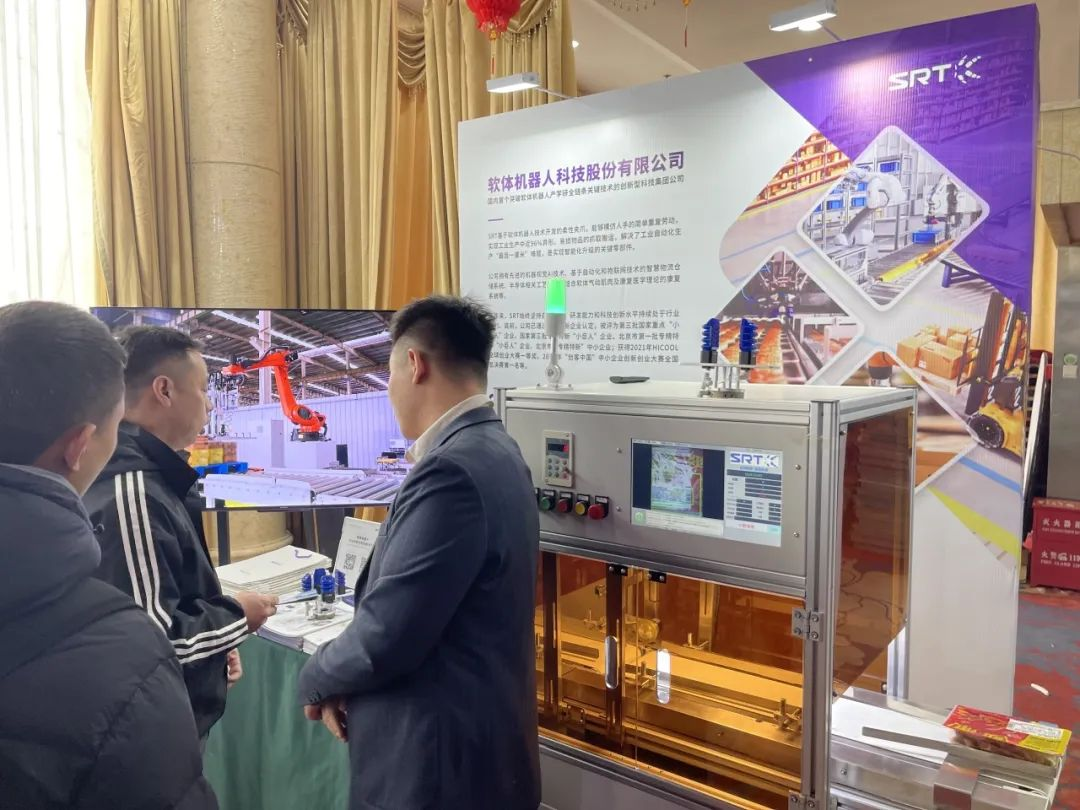

In the field of food automation packaging, SRT has the overall solution of automatic packaging visual inspection, the application platform of loading robot, etc., which can meet the differentiated needs of different prepared dishes enterprises through modular design. Among them, the air conditioning packaging visual inspection scheme exhibited at the current "Prepared Vegetable Industry Development Conference" is mainly used for the quality inspection of food packaging and the removal of defective products. The equipment can accurately detect foreign bodies (all kinds of hair, etc.) on the edge of food boxes. At the same time, it has higher detection accuracy for the diversity and inconsistency of defect parts such as the character of the label paper on the surface of the food box, pattern mounting, and reading one-dimensional code, and the missed detection rate is less than 0.01%.

【Air conditioning packaging visual inspection display scheme】

In the field of prepared vegetables logistics and storage, SRT has developed a fully automated production line of prepared vegetables, with prepared vegetables picking solutions, a new generation of "goods to people" warehousing and logistics solutions and group meals prepared vegetables automatic sorting and packaging solutions, to realize the automatic sorting and packaging of all kinds of food and fruits and vegetables.

Block the point and change the target

With "targeted" innovation, the prepared dish industry can burst into stronger vitality

From popular single products to personalized product processing, the automated production line continues to develop in the direction of scientific and technological innovation. However, for a long time, because of the long production time span, backward processing technology, domestic equipment constraints, difficult to trace the source, resulting in many problems in management, personnel application, and business processes, and even can not be effectively dredged for a long time.

In this context, SRT focuses on "targeted" innovation in product development to meet customers' needs for peer-to-peer and one-stop cooperation. To this end, in addition to flexible fixture products and solutions, SRT also has a series of intelligent equipment, such as intelligent shuttle vehicles, dismantling and picking workstations, dismantling and palletizing robots, etc., to assist SRT to complete the "targeted" needs of prefabricated vegetables customers.

For example, a group meal company through the use of SRT "goods to people" warehousing and logistics system, to achieve 1,000 food chain stores and primary and secondary schools of 50,000 meals a day supply. In addition, in continuous product innovation, SRT products and solutions help customers solve the following production bottlenecks, enabling the prepared food industry to burst out stronger vitality.

Results display

1. Eliminate the "acclimatization" phenomenon caused by long-term dependence on foreign imported equipment, and independently develop production equipment or production lines more suitable for domestic prefabricated vegetable enterprises;

2. Solve the problem of automatic handling and sorting of special-shaped and vulnerable items in the fresh prefabricated vegetable industry by using its own advantages of soft robot technology;

3. The automatic production line of prefabricated vegetables reduces personnel contact, has stronger quality control, and can trace the safety of ingredients throughout the process;

4. The product is suitable for dust-free purification workshop and refrigerated workshop, which improves the processing efficiency of food materials and reduces the premium of dishes caused by various expenditure costs;

5. The more flexible production space is convenient for responding to changes in the demand of the prepared vegetable market in the future, and can quickly respond and adjust the production line with explosive dishes at any time;

6 Products and solutions are deeply connected to the agricultural and food fresh industry, feeding the source supply system of food materials upward, and consolidating the standard production of prepared dishes downward.

At present, looking at the entire food field, SRT has helped many large customers to complete the construction and upgrading of production lines, including frozen steamed bun/dough/steamed bun/egg dumpling sorting, aquatic fish weight, bag instant noodle packaging production line, churro machine equipment production line, ice cream sorting production line and many other projects. Among them, the ice cream sorting production line helps customers to directly increase the yield of the original production line to 99.9%.

All the way through the thorns, SRT's ultimate vision is to use the value of the industry chain "from field to table" per kilometer service + to create a "tip of the tongue" intelligent assured factory for the majority of industry customers.