How can I benefit from total quality control?

The quality control of incoming materials/printed materials (product labels, instructions, etc.) directly affects the income and reputation of enterprises. The sampling inspection of packaging materials for manufacturing enterprises is indispensable. Do you also have the following challenges to solve?

● Hope to prevent printing accidents before they happen, and prevent defective labels from flowing to the market and facing recalls, rework and claims;

● Shorten the testing time while improving the passing rate of sampling.

The innovative application of image and text inspection machine

Accurate/fast/full language

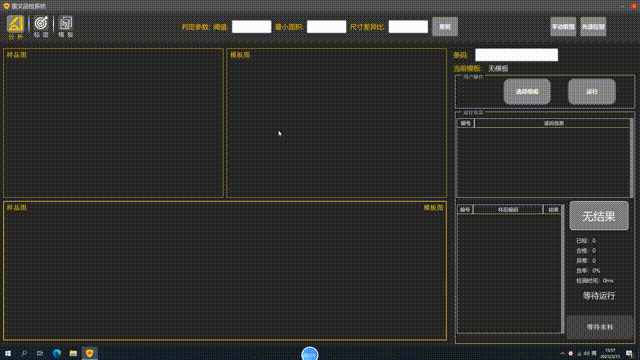

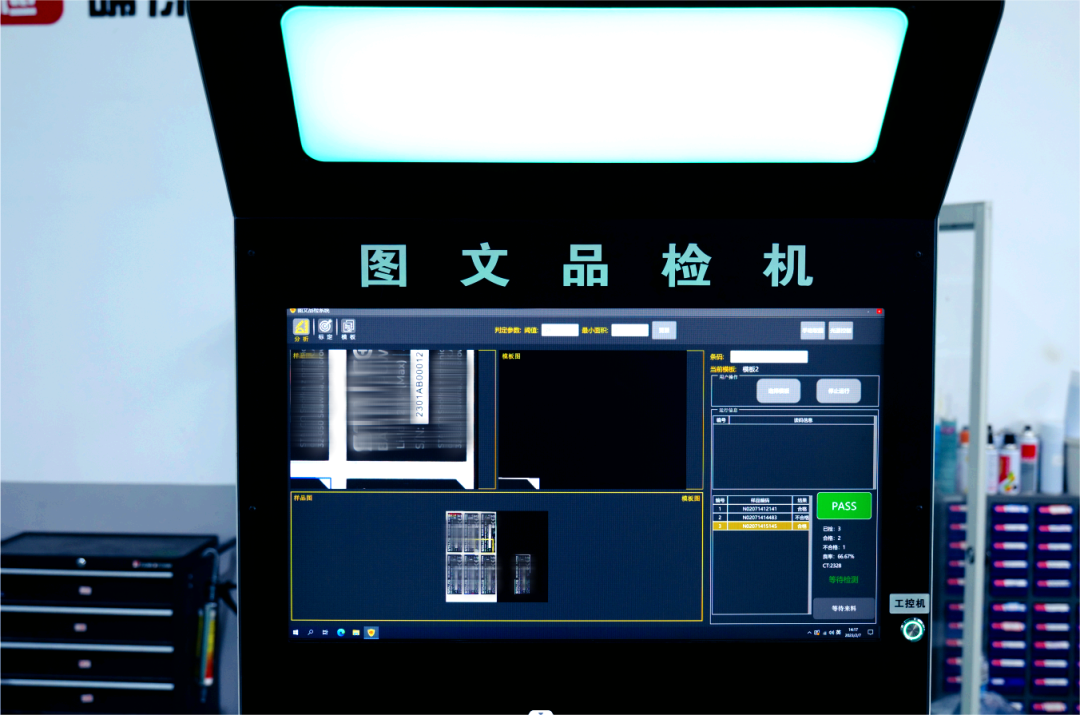

BOX (a subsidiary of SRT) launched the graphic product inspection machine for the warehousing department to provide quality control of printing packaging materials and sampling inspection, through the quality control of printing packaging inspection, avoid the "spillover" of defective products, to help manufacturers improve quality control strength and customer trust.

Situation of incoming materials/printed matter sampling inspection scene

The challenge of manual production capacity

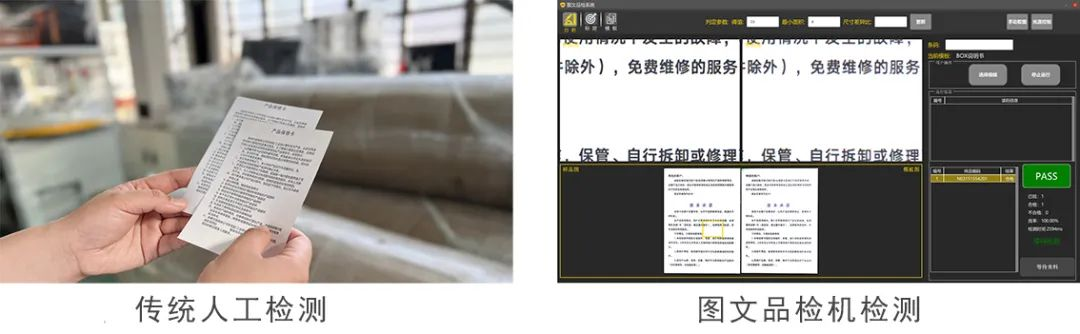

At present, the sampling inspection of incoming materials/printed matter in storage is still mainly based on manual visual identification. With the increasing complexity of product types and the accelerated pace of global product circulation, the market has higher and higher requirements for the printing quality of product packaging.

Compared with relying on artificial visual inspection, how to quickly find product label/manual surface defects, shorten response time, eliminate defective products and stop losses in time has become one of the pain points that discrete manufacturing enterprises need to overcome.

Graphic product inspection machine detection advantages

Demand synergy creates more corporate returns

In the actual production process of the label/manual, due to human omissions, ink printing errors and other factors, resulting in a variety of defects in the finished product label/manual, enterprises not only cause production costs to rise due to label invalidation, but also seriously affect product quality.

The graphic quality inspection machine is a visual equipment for the above problems, which is mainly used in the inspection of the quality defects of incoming materials/printed matter. It can quickly and accurately detect all kinds of adverse defects in print labels, improve product quality and production efficiency, and reduce enterprise costs.

Test product packaging labels, tags, instructions, etc., effectively identify product misprinting, leakage, multiple printing, mixing, printing dirt, damage, shape size, bar code content, position deviation and other common bad, to avoid the occurrence of production quality accidents.

01 High detection accuracy

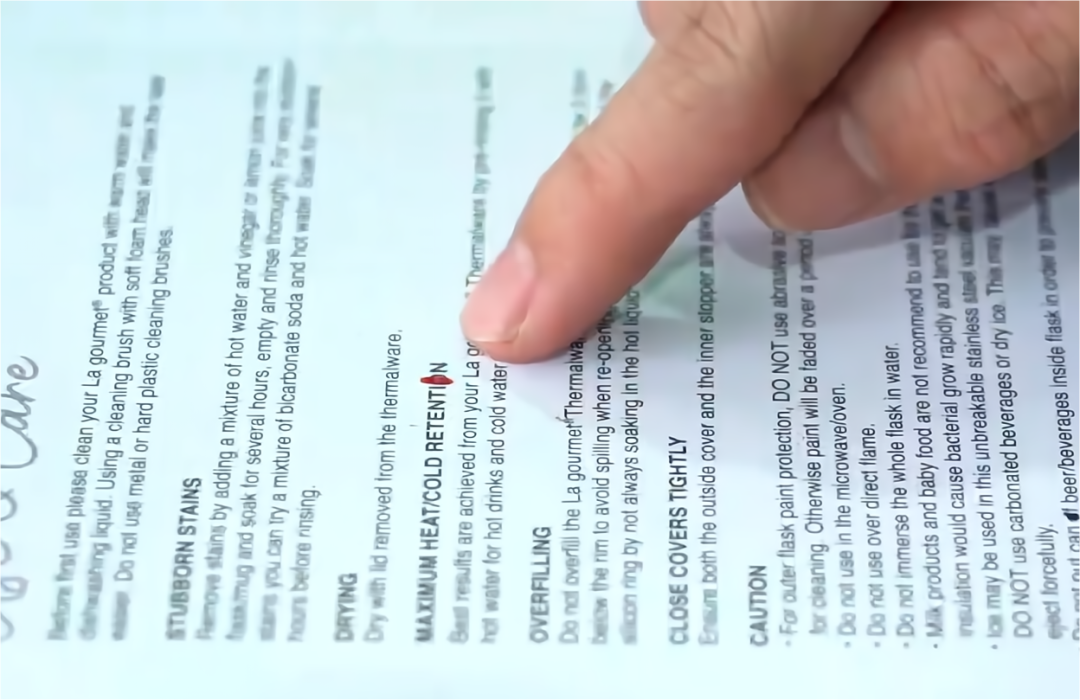

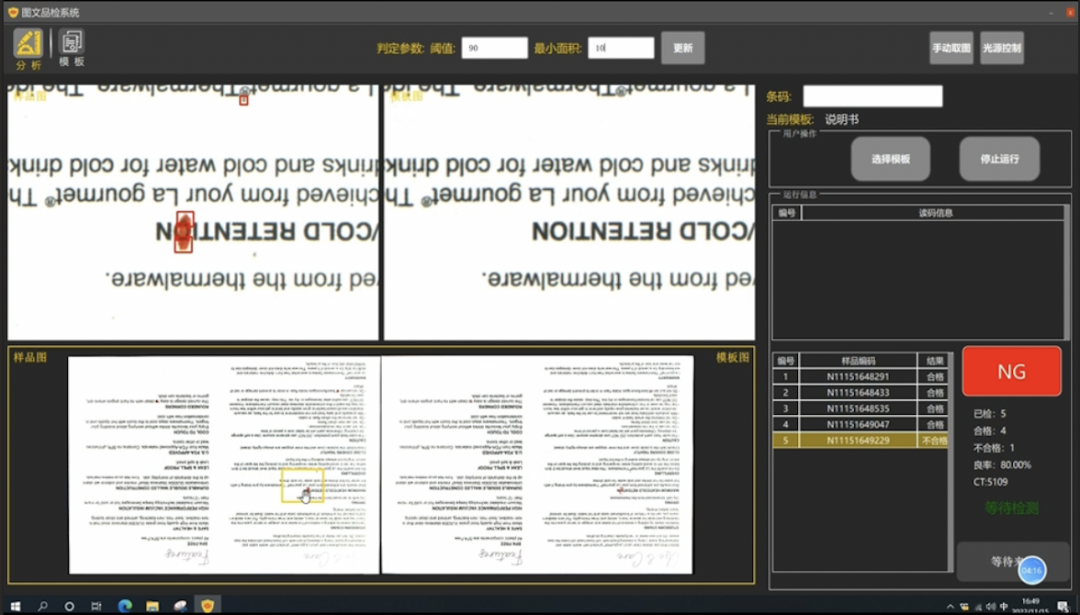

Different from manual detection, the detection accuracy of the graphic quality inspection machine can reach 0.2mm, which is the limit that the artificial naked eye can not work for a long time. By using the product template to be tested and sampling samples for image comparison, the abnormal place with alarm prompt and automatically delimit the defect location, to remind workers to remove in time.

It not only eliminates the misjudgment rate observed by the naked eye, but also avoids the risk of defective products flowing out due to label errors.

02 Fast detection speed

The manual detection method is easily affected by the language diversity of the monitored object, the complexity of the pattern, and the material and shape, and the details are not easy to find.

The graphic inspection machine can easily cope with these graphic differences, complex inspection can be completed within 3s, and the speed can be increased by more than 200 times.

03 Process control and information interconnection

Mechanical repetitive work is easy to make people feel tired, resulting in wrong detection and missed detection, and the manual detection process is not easy to control, and the detection results are difficult to trace. The graphic inspection machine effectively avoids the subjectivity and individual differences in the manual inspection process, and is more suitable for fine detection work.

In addition, the graphic inspection machine can be connected with PLM to realize automatic comparison of electronic documents. At the same time, with the help of data statistics and visual report presentation, it helps discrete manufacturing enterprises to make up for the problems of unit production and manufacturing collaboration.

Through comprehensive analysis and monitoring of various inspection data, help enterprises improve data traceability and quality control capabilities, quickly optimize business decisions, reduce costs for quality assurance, and accelerate the pace of delivery or time to market.

Value reengineering and broad application prospects

Business optimization Upstream and downstream enterprises to explore a new stage

Graphic inspection machines and visual inspection solutions can become a new choice for customers in many industries to improve printing quality, not only because of the unilateral value of eliminating missed and false inspection. Upstream customers can bring economic benefits and quality control benefits through the introduction of machine vision inspection technology, and can also form a good "quality reputation" for downstream customers, so as to strengthen close cooperation and establish a strong trust chain between enterprises.

From the perspective of market prospects, graphic inspection machines and visual inspection solutions can cover more than 80% of the entire industry's storage incoming materials/printed matter printing quality testing needs.

At present, the graphic product inspection machine has been applied in a number of head thermos cup manufacturers, as well as 3C, power tools, small household appliances, hardware, medicine and other industries of packaging material quality inspection. In addition, it can also be widely used in food fresh, clothing, textiles, business and other industries that require quality inspection of printing and packaging materials.