Modern enterprise definition of packaging

Packaging is not a very simple thing! For example, when moving to pack luggage, we will put clothes together, daily necessities into one category, and not commonly used in a box, so that when taking it will be more organized and convenient. The same is true of product packaging, but it is not a few pieces of luggage, but thousands of products produced by the assembly line, which requires intelligent and systematic design solutions.

In industrial manufacturing, if the front end solves the problem of product production, the rear focus is the packaging problem of the product. In the past, the production efficiency of enterprises was not high, often relying on manpower for product packaging; After entering the industry 4.0 period, fully automated, informationized and intelligent production lines have become the "standard equipment" of enterprises, and manpower alone can no longer meet the growing production needs.

At present, although the technical application level of the entire packaging industry has been improved, there are still a large number of enterprises that cannot establish an effective channel between "product packaging" and "assembly line service", which has become a problem to be solved urgently.

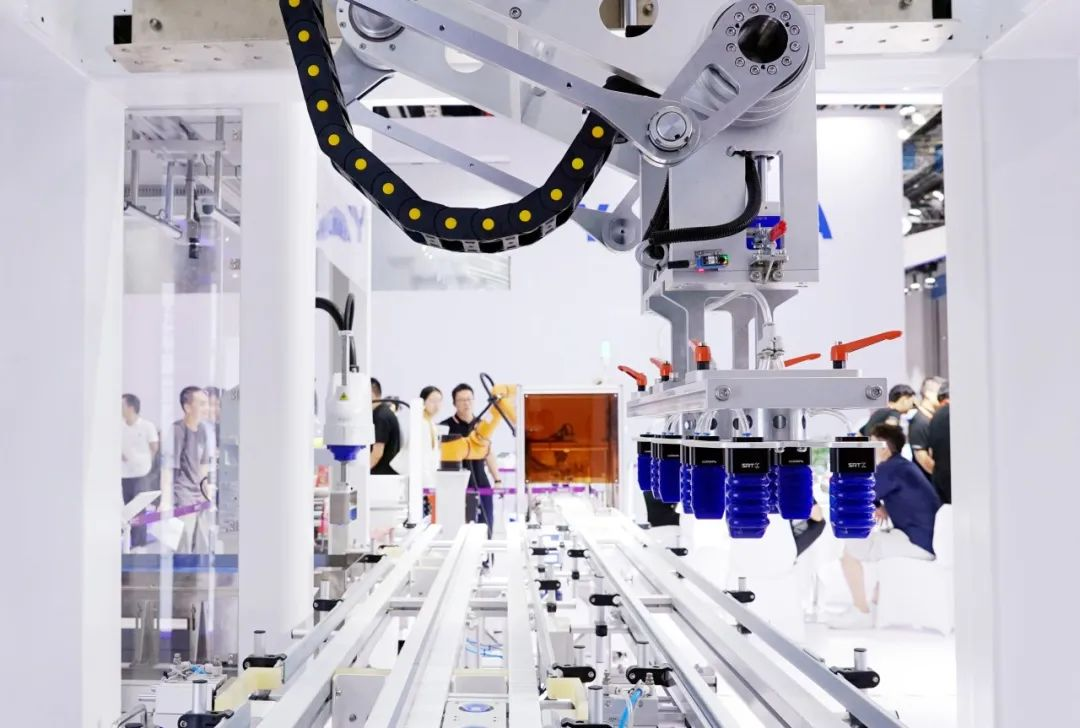

With years of accumulated experience in automated production line upgrading, SRT continues to broaden the boundaries of the industry and is advancing to the back-end packaging industry with high production efficiency, high automation, good reliability, strong flexibility and high technology content. By optimizing industrial robots, flexible end fixtures, machine vision, packaging machinery and equipment, etc., to create an integrated packaging application platform with simple freedom, medium and high load, flexibility, standardization, and compatibility with a variety of material handling unit mechanisms, that is, SRT loading robot application platform, Leading packaging production to the integrated, efficient, intelligent direction.

【SRT load moving robot application platform】

Let the packing line be organized

Leading the value revolution of the packaging industry

The packaging industry is complex. There are many kinds of product packaging, and the related product characteristics, packaging materials, and customer requirements are different; According to the survey, in the process of moving towards automated packaging, the packaging equipment has high requirements for the load capacity of the robot, but there is no clear requirement for the range of freedom of the robot. SRT load shifting robot application platform fully meet the market demand, remove the cumbersome packaging steps in traditional production, use technology to open up the production "break point", the original scattered packaging line into a whole, forming a full integration of the post-packaging new application.

【Standardized workstation for grasping, packing and conveying materials with visual inspection function】

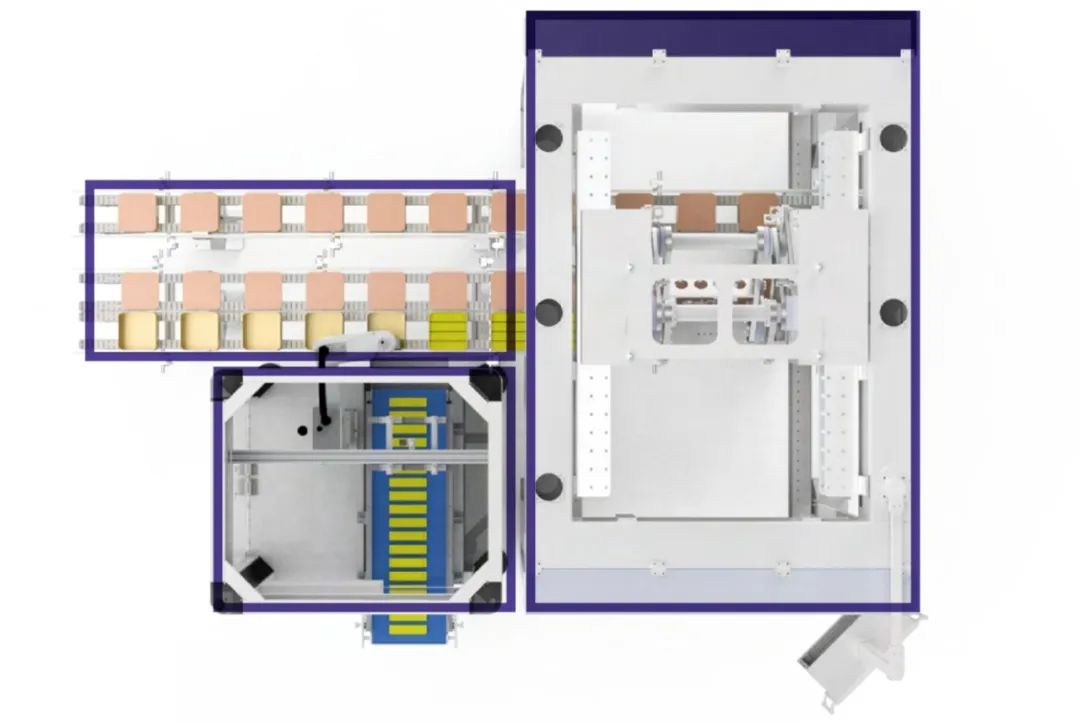

The SRT loading robot application platform is composed of three parts, which are the material handling and material management system, the standardization workstation of grasping and loading, and the standardization workstation of grasping and loading. The platform adopts modular design, and the single machine is closely connected into an automatic production line, which realizes the fully automatic operation of outer packing box/box conveying, material location detection, material grabbing, box filling, capping and packing, and the production beat is ≥20 times/minute.

【Grab and load standardized workstations】

Three way enabling cohesion

Improve packaging quality and production efficiency

In terms of material location detection, the combination of AI deep learning detection algorithm and traditional vision algorithm is used for detection, and the repeated positioning accuracy of the moving robot to grasp materials is high, which greatly guarantees the accuracy of the dropping position, and is fast and efficient.

In terms of material grabbing, the moving robot is equipped with multiple sets of gripper mechanisms of different structures, and adopts SFG flexible gripper independently developed by SRT to carry out operations such as grasping, packing, capping and packing. Flexible claw compatibility is strong, can adapt to a variety of material types and packaging material specifications; With quick change device to meet a variety of manual and automatic loading and unloading needs.

In terms of workshop deployment, the SRT load shifting robot application platform occupies a site of only 3*4.5m, of which each single machine is standardized design, small structure, can be placed in a suitable station after a variety of combinations according to the actual production process needs, to complete the layout of automated production lines, so as to meet the needs of various mass production.

【Flexible gripper for material grab】

Compared with the manual, the SRT load shifting robot application platform has increased the production efficiency by 30%, which can completely replace the part of the manual to ensure the 24-hour uninterrupted production of the production line, and truly realize the automated production of "high quality, high efficiency and low cost" for customers. The SRT mobile robot application platform is easy to operate and has a high degree of standardization, which is very suitable for the secondary packaging of the food industry (such as milk, chocolate, candy, biscuits, egg rolls, etc.); In addition, the platform can also play a high quality performance in the non-food industry (such as thermos cups, hardware, cosmetics, daily chemical products, etc.) in the box/container operation.

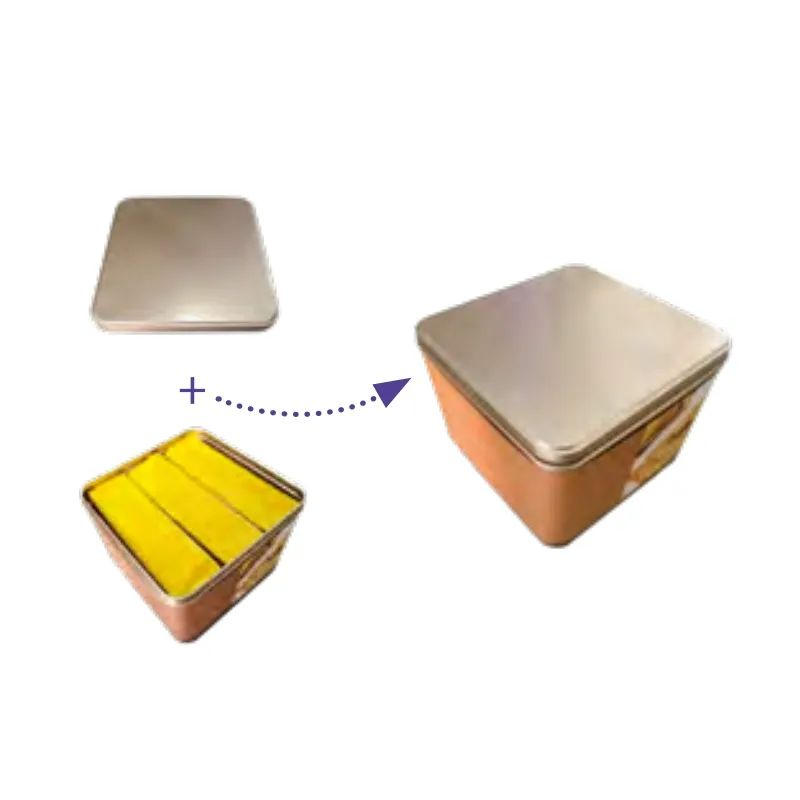

Food Industry 【 Bagged Egg roll packaging Case 】

In this case, the SRT robot application platform is used to complete the whole process of material conveying, grasping and filling boxes, covering boxes, etc., which greatly improves the production rhythm for customers and drives sales to create more economic value.

Conveying and handling system

The first step is to put the box cover, box body and other materials into the "conveying and material management system", and only use very little manual feeding with the box body;

Grab, pack and transport materials

In the second step, in the standardization workstation of grasping and packing and conveying materials, the visual detection position grabs materials from the conveying line through the load shifting robot, and then boxes them in turn.

Load and cover boxes

After the third step is completed, the items flow into the "grabbing and loading standardized workstation", and the two-axis robot is used to grab the box cover and cover the box, and finally output the finished product.

The mobile Robot application platform is a microcosm of SRT's integration of product collaborative innovation, technology leadership and integrated solution supply capabilities. SRT has long been committed to the independent research and development of i-EOAT innovative end effectors. In recent years, thanks to the transformation and upgrading of domestic manufacturing industry, it has driven the explosive growth of automated, intelligent and digital production equipment. During this period, SRT has been continuously upgrading technology in combination with a large number of production cases, gradually extending from the production of a single industrial end actuator to the upstream and downstream of the industrial supply chain, and has initially grown into an overall solution service provider that can provide the whole life cycle, and will continue to create greater production value for the majority of industry customers, and boost the leap and upgrade of new quality productivity with scientific and technological innovation.