Current situation of traditional temperature measurement technology

The process of temperature measurement is many and time-consuming

As the core function of the thermal insulation cup, the thermal insulation performance needs to undergo three temperature measurement and repeated inspection in the complex process to reduce process loss and ensure product quality.

Industry pain point problem

Artificial uncertainty caused by environmental factors

The traditional temperature measuring machine uses hot air pipe for continuous heating, and then human hands touch and sense to judge whether the cup wall is hot for quality inspection. It not only relies on manual experience, but also has high energy consumption of the equipment, resulting in the operating environment temperature of more than 40℃ in summer, and there are difficulties in hiring, quality control, cost reduction and automation.

Productization challenges for thermos measurement applications

The technological revolution is accompanied by four difficulties of product breakdown

failure-prone

Stainless steel surface highly reflective

It is sensitive to external interference and easy to fail temperature measurement

Poor accuracy

Ambient temperature fluctuation

Camera drift and deviation result in poor accuracy of direct measurement

High difficulty

Small batch, multi-variety production

The product is not fixed, and the algorithm is difficult to generalize

Many restrictions

Replace artificial perception, reduce people and increase efficiency

Product design is more restrictive

Innovation breakthrough

Heat shadow thermometer by "wisdom" on

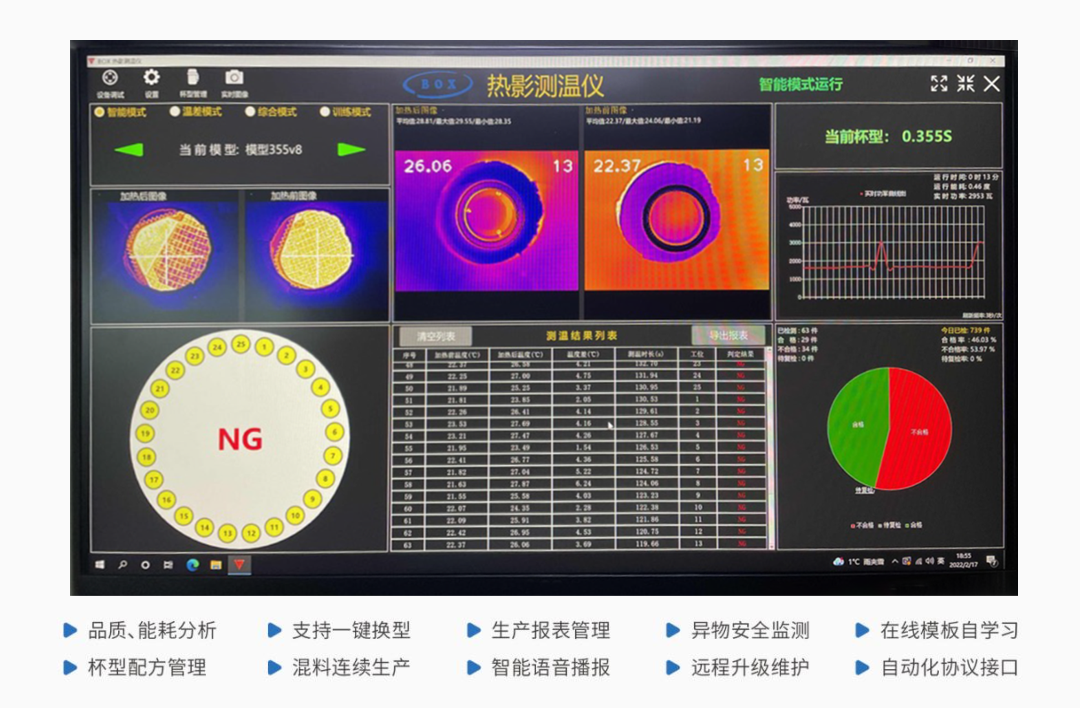

The introduction of thermal imaging machine vision and artificial intelligence technology can accurately determine hot cups, warm cups and good cups according to customer requirements, so that the temperature measurement process of thermos cups can be automated and digitized, which not only reduces energy consumption, but also achieves good social and economic value.

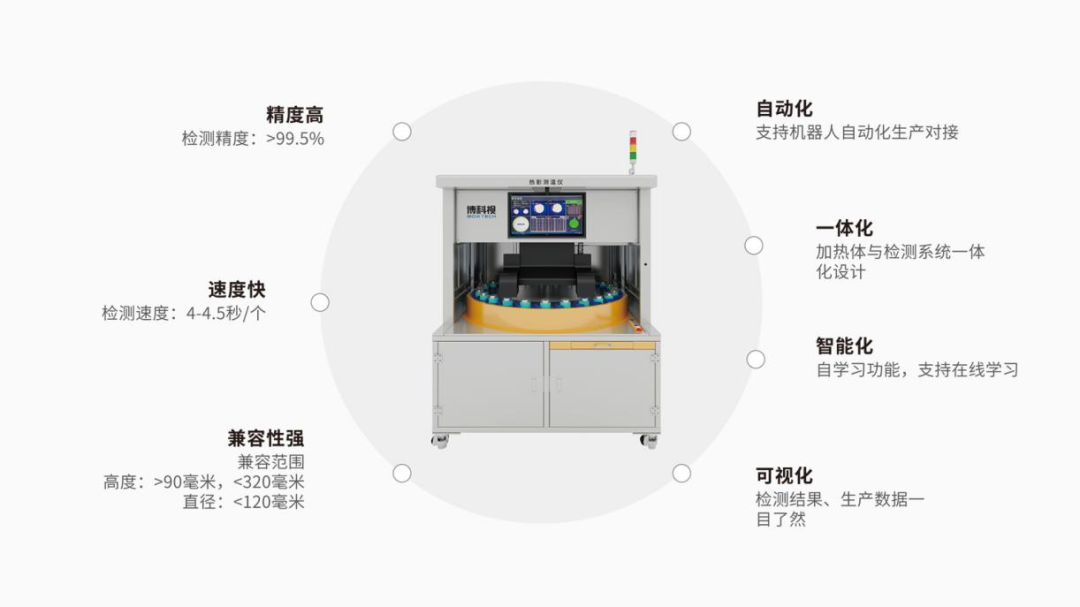

Core features and advantages

Work stable, accurate, specialized, refined, fast

Compared with traditional thermometers, the main advantages of thermal shadow thermometers are accurate temperature measurement, energy saving and low carbon, and support for automation and digitalization.

Thermos cup temperature measuring automatic line

High capacity, two temperature measurement methods to widen the installation path

There are two main application ways of automatic temperature measurement: centralized temperature measurement and wired temperature measurement.

The centralized temperature measuring line uses three thermal shadow thermometers in series, and three robots work independently through the central control system, which can realize the temperature measuring capacity of 2.5W cups in a single shift.

Centralized loading and unloading, personnel efficiency is higher

A two-channel temperature measurement can be reused to improve the utilization rate

Each unit can be produced independently for increased flexibility

Central control platform one key type change, digital Kanban improve management efficiency

Average hourly capacity: 2400-2550 / hour

Wired temperature measurement is installed on the production line, which can directly replace the manual temperature measurement operation, without transport, small investment and fast return.

It can be quickly embedded into the production line to achieve automatic temperature measurement and reduce personnel

After enlarging or cascading the cache area, one person can manage multiple thermometers

Capacity: 800-850 / hour

Practice case sharing

Production capacity release, help thermos cup customers to seek incremental space

Company introduction

Zhejiang Fuchuan Household Products Co., Ltd. was founded in 2011, is located in Jinhua City, Zhejiang Province, is a professional production of stainless steel vacuum insulation ware "high-tech enterprises", its products are exported to Europe, the Middle East, Southeast Asia and other countries and regions.

Key points of construction

The thermos cup automatic temperature measuring line is deployed in the temperature measuring workshop on the first floor of Fuchuan New factory. Three thermal shadow thermometer robot workstations are used in the production line, combined with the lifting conveyor platform, the central control system and the digital platform, which together constitute the thermos cup intelligent temperature measuring workstation.

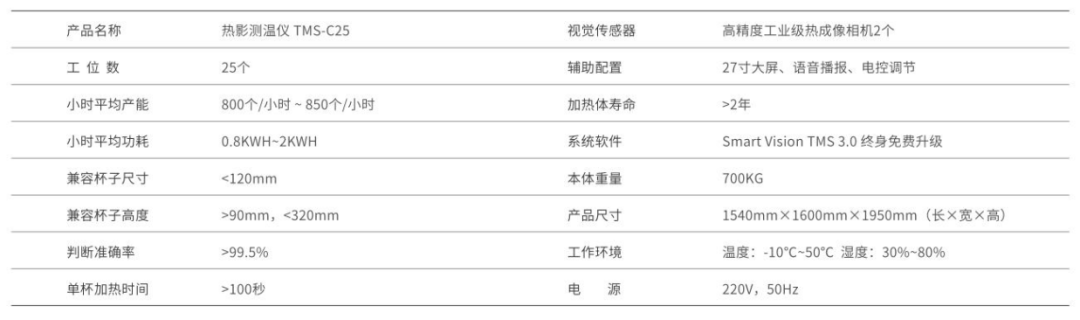

Product name: Thermos cup intelligent temperature measuring workstation TMS-C25-3

Size: L7000mm*W2500mm*H2000mm

Accuracy: >99.9%

Power supply: 220V, 50Hz

Project effectiveness

The data show that the thermos cup temperature measurement production line can simultaneously meet the needs of customers to improve production capacity, reduce labor/rework, save energy, reduce consumption and improve management, and help realize the takeoff of digital intelligence.

Average hourly capacity: 2400-2550 / hour

Single class: 2.5w

Reduce personnel and increase efficiency: the operating staff is reduced from 4 to 2 people

Energy saving: Daily energy consumption is reduced from 450KWH to 90KWH

Reduce rework: the yield is increased to more than 99.9%, reducing rework by about 2%

Management improvement: digital and traceable quality control management

Return cycle: The expected single-shift investment return cycle is about 1.6 years, and the double-shift investment return cycle is about 0.8 years

Broad application prospect and development space

The industry demand is large, and the usage rate of head customers is high

In China, 70% of the thermos cup manufacturing is concentrated in Yongkang, Zhejiang, known as the "world hardware capital", and its annual output of thermos cups can reach 600 million. This shows that in Yongkang region alone, the demand for temperature measurement has exceeded 1.8 billion times.

Automatic temperature measurement line solutions can cover 95% of the thermos cup testing needs, so many thermos cup manufacturers have joined the "army" to promote the digital transformation of the factory. At present, many industry head customers such as Panmo division, Ansheng, Xiongtai, Fuchuan, Feiyang, Aodu, etc., have successfully applied the program to the production line.