Head-mounted N95 mask

What kind of automated production line can easily meet the production capacity needs of mask manufacturers "99-120 pieces/minute"?

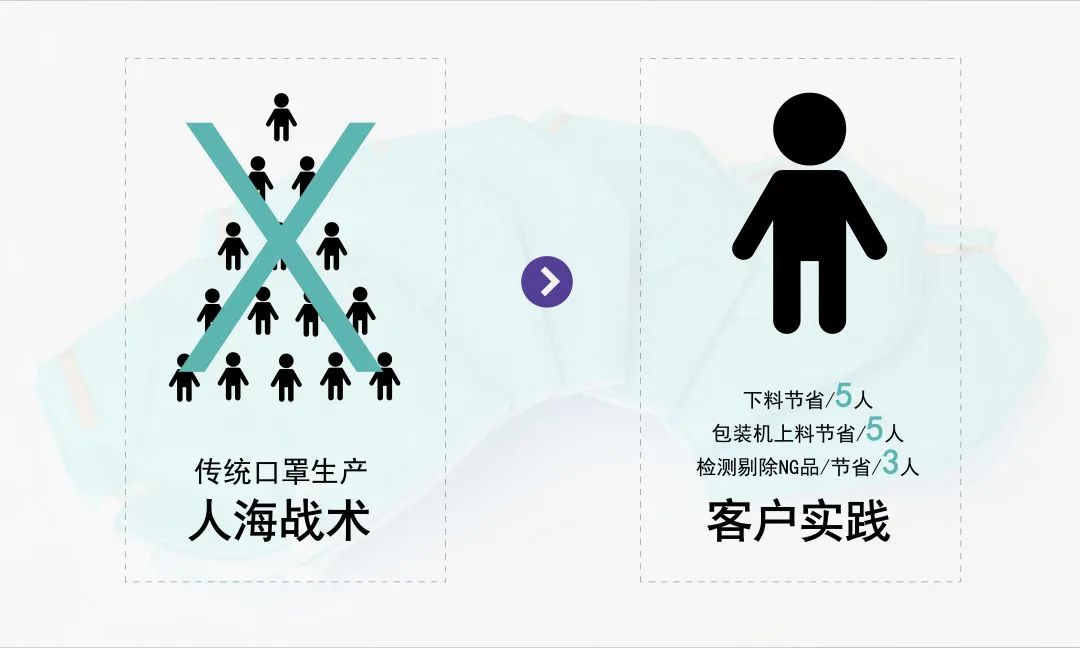

What is the key technology that can help the company reduce from the original production line of at least 10 people to the current 1-2 people, and can do all the work?

In the first half of 2023, SRT built a fully automated "head-mounted N95 mask testing filler line" for a large medical dressing manufacturing enterprise, which is mainly used for automatic feeding of finished N95 masks from ear band machine, and fully automated process operations such as visual inspection, automatic folding of ear band, finished product feeding and packing.

According to the data, with the application of automation technology, the head-worn N95 mask detection filler line can carry out technical innovation on the traditional more complex finished mask process, and can complete the production capacity of 8-10 people at one time.

Automated process operations

The Head-mounted N95 Mask inspection packing line has a highly automated process operation to meet high volume, fast production beats. According to the layout of the customer's existing production line and the requirements for production capacity, SRT engineers have made automatic layout in the key links of the entire production line:

According to the different production capacity of different customers, the production line can realize the free docking of the number of ear belt machine stations; The number of feeding stations can also be adjusted according to the actual working conditions;

The mask is transmitted using multiple stock brackets and subjected to strict visual inspection on the conveyor belt, with automatic elimination/recycling area for unqualified products, which is more efficient;

The use of SRT flexible gripper instead of human hands to realize the loading work of the mask, to fully protect the cleanliness of the mask and avoid man-made pollution;

Unique ear band folding technology, with a special material grab, can complete the simultaneous grasp of 9 masks at one time, and can achieve 90° flip and move to the plastic sealing machine into the packaging process;

It has strong scalability and can accurately connect the packing, testing, packing, packaging and other processes in the later stage of the mask to meet the needs of production capacity.

Head-mounted N95 mask packing line

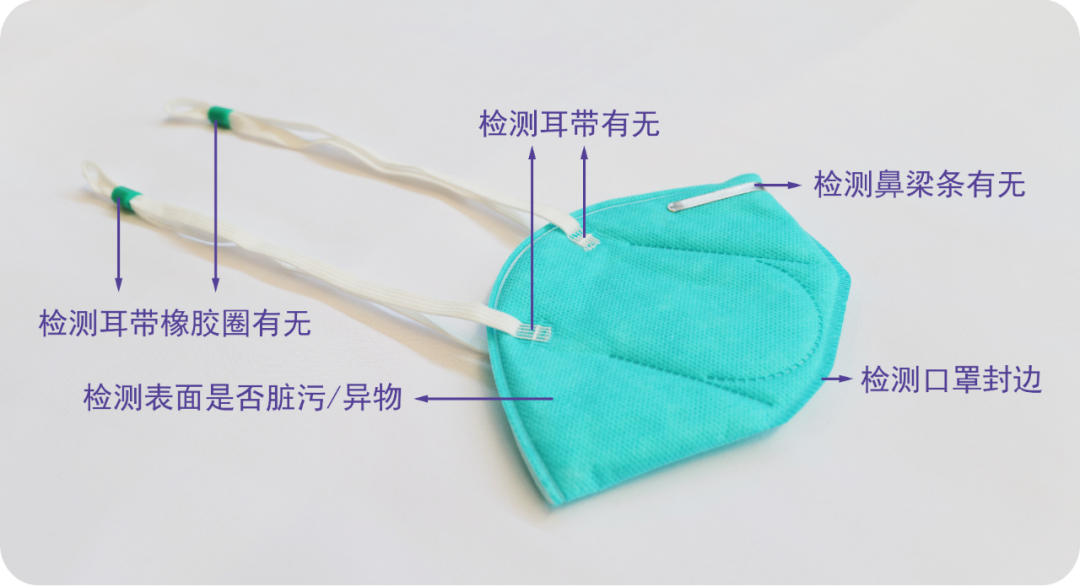

AI visual inspection

Based on the MVP algorithm platform, the head-mounted N95 mask detection filler line introduces AI deep learning technology to form a new "AI algorithm training modeling detection scheme", which can realize the all-round detection of product quality as long as one process, so that mask manufacturers can realize the rapid deployment and production of the production line.

Defect detection quality assurance

Automatic elimination of efficient production

One-click replacement rapid deployment

The head-mounted N95 mask detection packing line can achieve 7x24 efficient operation, the product quality inspection post does not need manual, and the central control platform gives real-time feedback to the detection data to ensure the safe and efficient production of the enterprise in an all-round way.

Head-mounted N95 mask packing line

Simplifying processes saves labor

N95 masks need to go through many processes in the entire production process, and after the completion of the previous process, it is immediately transferred to the next process. Multiple transshipment not only consumes workers' time, but also results in heavy workload and reduced efficiency.

Secondary transshipment not only consumes workers' time, but also results in heavy workload and reduced efficiency.

The head-mounted N95 mask detection packing line solves the problem of finished N95 masks in multiple processes, and the integrated design is not only reflected in the simple "to remove labor and control costs", but also saves the time of frequent and multiple transfers of workers, and can avoid the secondary pollution and artificial damage that may occur during the transit of masks.

Head-mounted N95 mask packing line

In the process of customer use, according to the corresponding needs, the current head-mounted N95 mask detection filler line front end mainly connected to the ear belt machine, the ear belt produced in the N95 mask, after the detection process and fold the ear belt into the film groove of the plastic sealing machine, can easily meet the customer's current speed of 100 pieces/minute.

In addition, the head-mounted N95 mask detection filler line can also accurately connect all the processes of the post-packaging, open up all the work processes, and form a complete N95 mask packaging/packaging fully automated assembly line.