01 Although the market is big, there are challenges

Recently, the U.S. Department of Agriculture released the latest outlook on global beef, pork and chicken production and trade: global beef production in 2023 is expected to be 59.2 million tons; pork production will increase to 111 million tons; at the same time, chicken production will reach 102.7 million tons. With the rise and popularity of the concept of soft robotic grippers, the global raw meat (protein) processing industry is turning to automated production at an increasing speed.

However, adoption of robotic automation in the food industry has been relatively slow. Although the market potential is huge, most food manufacturers are still stuck in production bottlenecks, mainly due to:

1 High standards and strict food hygiene conditions

Fresh meat sorting equipment, as a direct "contact", needs to abide by strict food safety standards;

2 Mature mechanic costs that cannot be maintained for a long time

Manufacturers are unable to recruit and retain skilled labor over the long term to respond to adjustments to increase productivity, reduce costs, and increase revenue;

3 Non-standardized characteristics of the product

The shape of raw meat is irregular, highly variable, and the sticky surface cannot match the high-speed sorting requirements of automated equipment.

02 The plan is in hand, I have the advantage

The emergence of automation technologies such as soft robotics and machine vision provides manufacturers with an efficient means of increasing production. Since its establishment, SRT soft robots have actively responded to customers' needs for food manufacturing, and have continued to create feasible automated picking solutions for customers with flexible end grippers as the core.

Before the introduction of soft robot technology, more than 90% of the original meat customers in the world had sorting and packaging work done manually. Manual operations are affected by factors such as the working environment (big smell/low temperature), repetitive labor, epidemic infectious diseases, and the difficulty of monitoring the sorting process and the difficulty of tracing the source of responsibility. The long-term mechanism cannot be formed, and the variables are large. The need for "machine replacement" is urgent.

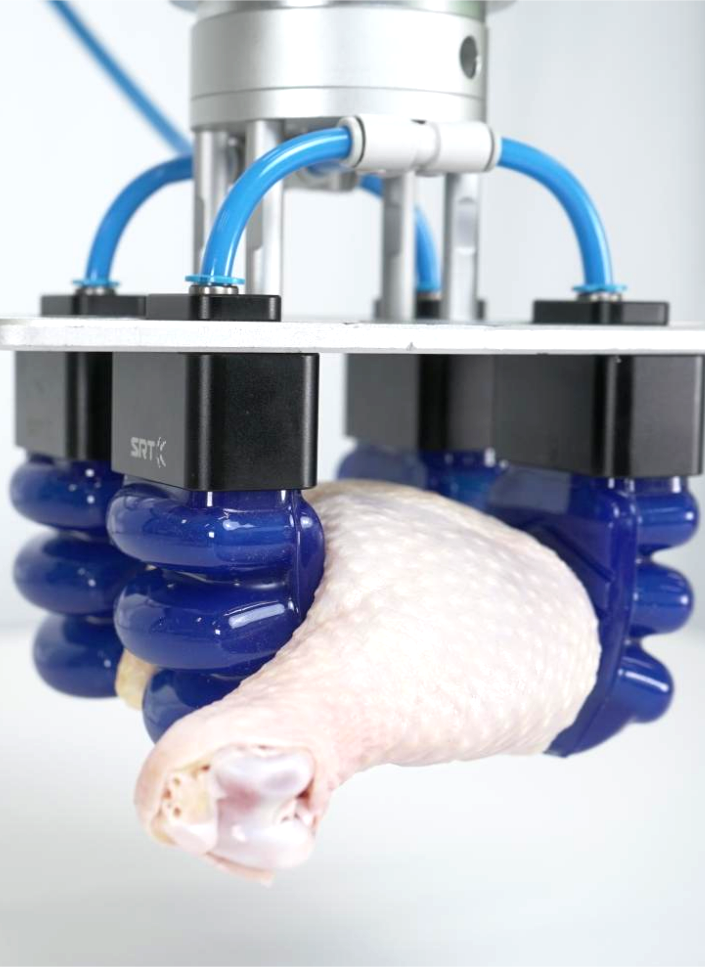

At SRT, the SFG flexible gripper based on soft robotics technology can generate rapid deployment, reliable and safe, and automated flexible solutions with 3D visual perception.

SFG flexible grippers have natural advantages in the field of fresh meat processing. It can work continuously around the clock in humid cold rooms, greenhouses, high-temperature workshops, etc., and is good at non-contact workflows.

In response to seasonal surges in demand, the client does not need to recruit additional temporary workers because it can meet productivity needs. The advantages of flexibility and easy programming can also be redeployed to new product lines or different processes.

03 Wide application of multiple SKUs

For a long time, the topic of product SKU has always troubled many enterprises. Under the personalized market demand, according to the development of Industry 4.0, customers need a more powerful technical force, which can simulate human action mechanism, break through the contradiction between multi-variety and small batch production and flexible operation like human beings, and realize flexible production , to meet the production requirements of different products and different processes. In long-term customer applications, the SFG flexible gripper not only has a simple structure, is stable and reliable, and has many assembly methods, but also has a wide range of application fields and a very broad market prospect.

The scope of application of SFG in raw meat sorting

Fresh poultry meat: fresh chicken wing/chicken leg/chicken breast/chicken duck neck and other fresh poultry cutting products;

Fresh beef and pork: sorting and boxing of fresh meat cutting products such as beef (pig) meat pieces/beef (pig) meat pies/beef (pig) steaks/beef (pig) ribs/pig trotters/cut pork belly ;

Quick-frozen meat products: hot pot ball slides/all kinds of sausages//fast-food meat products sorting machine boxing, etc.;

Seafood and aquatic products: sorting of fish fillets (pieces)/squid rings/shrimp/bags of seafood, etc.

Typical meat handling scheme reference

【Chicken Chop/Chicken Breast Grab】

Product features: irregular shape, soft and slippery

Weight specification: about 120g (length 80-100mm or 100-130mm)

Gripper selection: SFG-FNM2-N6064 (can be customized according to actual working conditions)

【Chicken Wings Box】

Product features: obvious skeleton structure, smooth surface and obvious oil stains

Weight specification: about 85g (length 65-80mm)

Gripper selection: SFG-FNM2-N5056 (can be customized according to actual working conditions)

【Fresh Pork / Trotter Sorting】

Product features: heavy weight, cylindrical shape, difficult to grasp

Weight specification: about 430g (length and width 175×45mm)

Gripper selection: SFG-FNM4-N5041LAe-N2105 (non-standard fixture)

A number of practical cases have shown that SRT can unlock the problem of automatic production line sorting for the meat industry with a global output of 272.9 million yuan, boost the continuous innovation of global meat companies in terms of products, technology, and infrastructure, and eliminate the dependence on manpower , to achieve an overall improvement in the production of meat products.