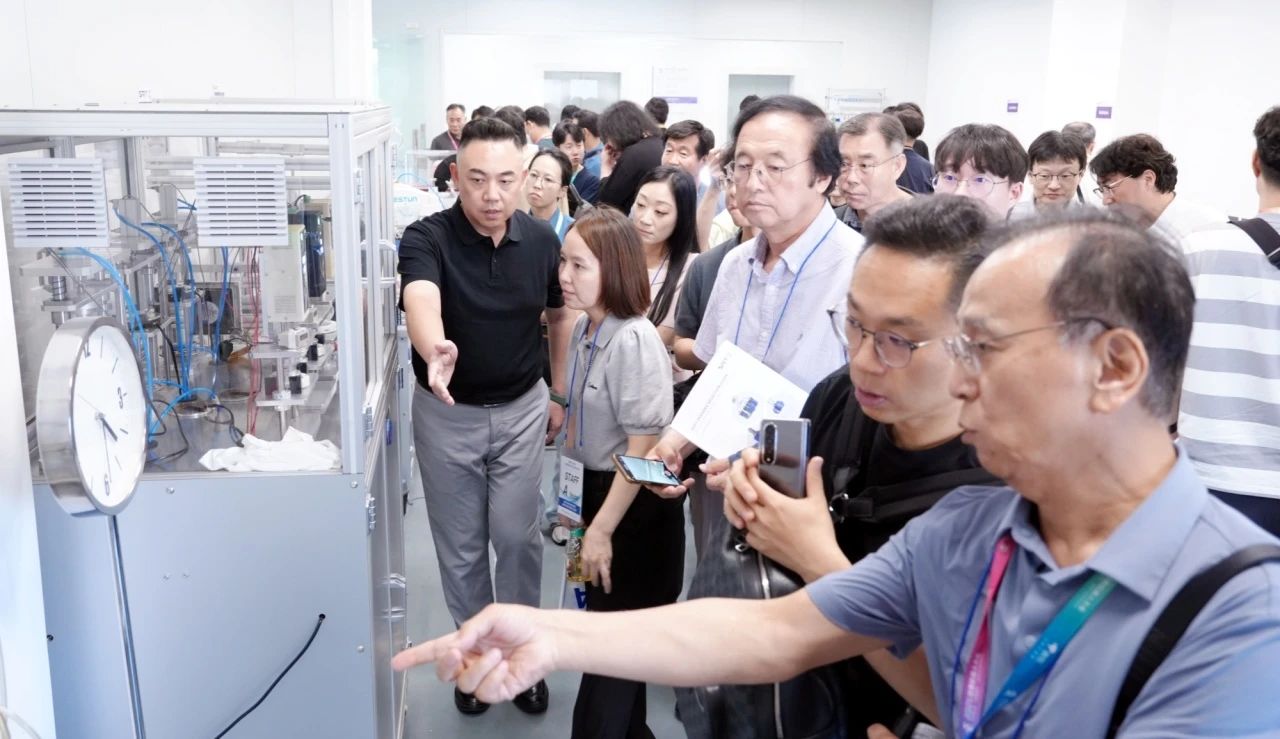

On August 9, 2025, during the 2025 World Robot Conference, more than 60 representatives from South Korean industrial manufacturing companies, technology research institutes, and local governments visited Beijing Soft Robot Technology Co., Ltd. (SRT). As an "old friend" of the World Robot Conference, SRT takes this cross-border exchange as a link to extend the international cooperation spirit of the conference to industrial practice, using core technology of soft robots as a pivot to showcase China's innovative strength and inclusive value in intelligent manufacturing.

This visit is seen by both sides as a "special collaboration" for the 2025 World Robot Conference. The 2025 World Robot Conference gathers support from 28 international organizations, focusing on "technology integration" and "innovative applications", while SRT enables global collaboration from exhibition booths to enterprises through on-site demonstrations. The South Korean industry delegation conducted a close inspection of SRT's industrial intelligence solutions with soft robot technology as the core. From biomimetic driving of pneumatic muscles to adaptive operation of flexible fixtures, from assembly of flexible production lines to full cycle services of overall digital solutions, they intuitively felt how technological breakthroughs reshape production paradigms.

As an industrial service enterprise with soft robot technology as its core, SRT has always been guided by the principle of technology accessibility. Based on the deep integration of biomimetic technology and core aerodynamic technology, SRT has built a three-dimensional innovation system of "technology scene ecology", which has achieved full chain capability from core components to complete automation systems. In the fields of fresh food, 3C, automotive parts, etc., flexible automation solutions are breaking down the rigid barriers of traditional production, allowing global small and medium-sized enterprises to share the dividends of intelligent upgrading.

This exchange highlights the collaborative trend of global intelligent manufacturing. The purpose of the South Korean industry delegation's visit is to conduct an in-depth investigation of the Chinese robotics industry chain. During the visit and exchange, SRT particularly shared the latest research results in artificial muscles, human skin, and biomimetic brains, and highlighted SRT's independently developed product series, as well as SRT's domestically produced alternative products in the field of semiconductor wafer transmission. Through the comprehensive adaptation of technology and application scenarios, enterprises are solving the global problem of "rigid demand flexible supply" in traditional industries.

At present, SRT has established partnerships with major clients in 16 countries, and its global service network is injecting the flexible advantages of soft robotics technology into diverse industrial scenarios. From the efficiency revolution of automated sorting to the safety upgrade of flexible handling, technological innovation is crossing geographical boundaries and becoming a link connecting global manufacturing. The in-depth visit of the South Korean delegation further foreshadows new possibilities for cross-border industrial cooperation.

The company leader stated, "We look forward to using software robotics technology as a link to inject Chinese innovation into the international industrial chain and promote the collaborative evolution of global intelligent manufacturing standards

Against the backdrop of promoting global intelligence integration at the World Robot Conference, SRT is outlining a clear blueprint of becoming a core supplier of intelligent equipment for AI factories by 2030, with technological innovation as its pen. This concept of "replacing boundaries with technological dialogue" is not only a practice of the spirit of the conference, but also a microcosm of the resonance between China's intelligent manufacturing and global industries - when flexible technology meets global collaboration, the future of intelligent manufacturing is moving from vision to reality.